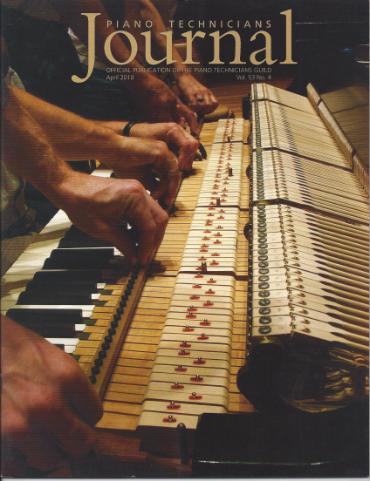

Dear technicians: Since January of 2008 it has been my privilege to be able to write a monthly series (Small Shop, Big Results) for the Piano Technicians Journal, the official publication of the Piano Technicians Guild. The Guild is a wonderful organization, full of technicians dedicated to their craft who have the best interest of both their own clients, and of fellow technicians at heart. Learn about the Guild at www.ptg.org.

The Journal is a great magazine which has been published since January of 1958. I personally own and treasure every copy of the magazine from that premier issue, and have enjoyed every article published.

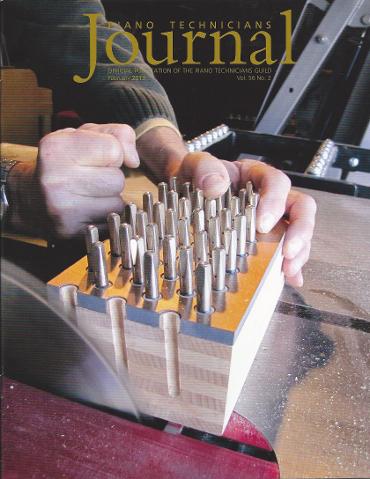

What follows are the original drafts of the segments of the "Small Shop, Big Results" series which I submitted to the editors of the Journal for publication. (Differences in text do occur between the draft copy and the finished copy as they appear in the magazine. Occasionally, photos in the original draft are not used in the magazine for reasons of space.)

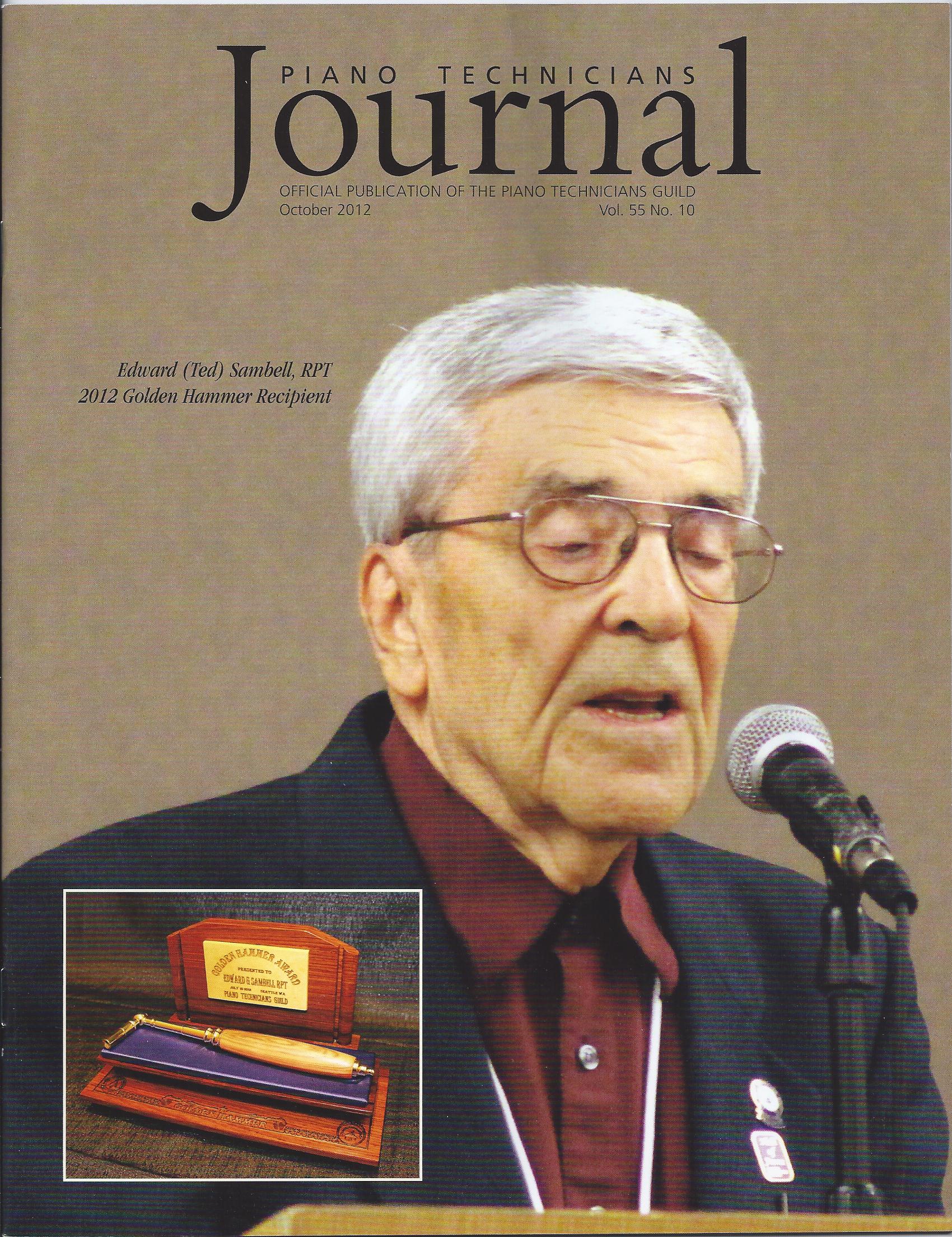

The cover photos used for reference are copyrighted by the Journal and are used here with permission of the PTG.